Top Trends in Branded Clothing That You Need to Know About

Top Trends in Branded Clothing That You Need to Know About

Blog Article

The Rise of DTF Printing: Exploring Its Advantages and Applications

The emergence of Direct to Film (DTF) printing technology is transforming the custom-made garments market, supplying significant benefits and a large selection of applications. Its one-of-a-kind capacity to generate premium, dynamic prints on different fabrics without the necessity for pre-treatment considerably optimizes production processes and boosts functional performance. DTF printing's flexibility to both huge and small production runs makes it an attractive option for developing tailored products, such as sports team attires and business marketing merchandise. As the cravings for personalized products remains to expand, understanding just how DTF printing can satisfy these advancing needs is significantly vital.

Recognizing DTF Printing Innovation

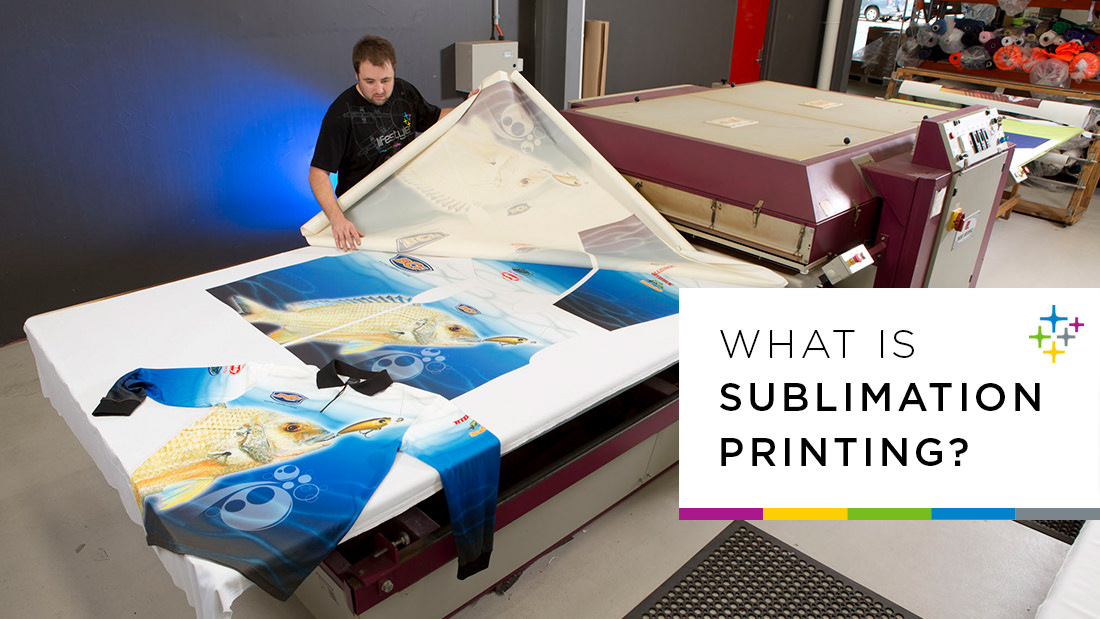

Comprehending DTF Printing Technology marks a substantial development in the fabric printing industry, especially for its convenience and efficiency. Direct-to-Film (DTF) printing is a sophisticated process that includes printing layouts onto special transfer films, which are then transferred onto material utilizing warmth and stress. Unlike conventional approaches, DTF printing does not call for pre-treatment of the fabric, allowing a much more structured workflow.

Once cured, the movie is positioned onto the textile, and a warm press transfers the style by applying consistent warmth and stress. This leads to lively, high-quality prints that stick flawlessly to numerous material types, consisting of cotton, polyester, and blends (screen printing). The modern technology's capacity to create complex and vibrant layouts with marginal arrangement makes it a game-changer in the fabric printing field

Key Benefits of DTF Printing

One of the key advantages of DTF printing is its exceptional convenience, which enables high-grade prints on a vast variety of fabric types. This capacity prolongs beyond typical cotton to consist of polyester, nylon, leather, and even combined materials, making it optimal for diverse textile applications. This adaptability lowers the demand for multiple printing technologies, improving production processes and decreasing overall costs.

An additional significant benefit is the exceptional print top quality that DTF technology provides. By using dynamic, sturdy inks and precise application techniques, DTF prints keep their color integrity and intensity even after many washes. This leads to an item that not just looks professional however additionally stands the test of time, supplying consistent value to both end-users and manufacturers.

Furthermore, DTF printing supplies a streamlined workflow, which can result in boosted performance and productivity. Unlike conventional techniques such as display printing, DTF does not call for intricate setup or comprehensive drying out times. This convenience of usage makes it an attractive choice for services of all dimensions, permitting quicker turnaround times and the capacity to handle small to big manufacturing keeps up marginal hassle.

Applications in Custom-made Apparel

In the realm of customized apparel, DTF printing sticks out as a game-changing technology that makes it possible for suppliers and developers to generate bespoke apparel with unparalleled detail and top quality. Direct-to-film (DTF) printing has revolutionized the customized fashion industry by providing adaptability in layout, brilliant color recreation, and longevity. This ingenious method permits for complex designs to be moved onto a broad array of materials without compromising the honesty of the material.

One substantial application of DTF printing is in developing personalized tee shirts, hoodies, and sports apparel. The capability to print complicated graphics with fine information and gradients makes it ideal for personalized garments, such as team uniforms and advertising merchandise. In addition, DTF printing is particularly useful for limited-run orders and one-off pieces, offering a cost-efficient and effective remedy compared to have a peek here typical screen printing check out here techniques.

In addition, DTF printing has opened brand-new methods for stylist to explore unique patterns and textures, allowing the development of cutting-edge, progressive collections. This modern technology additionally supports small companies and independent musicians by lowering the obstacles to entry in the customized clothing market. Eventually, DTF printing is reshaping the landscape of custom-made garments, combining imaginative expression with technical innovation.

Versatility Throughout Different Products

Building on the advancements in personalized clothing, DTF printing's flexibility across various materials better improves its appeal. Unlike typical printing techniques, DTF (Direct-to-Film) printing can be applied to an extensive array of substrates, consisting of cotton, polyester, blends, natural leather, and even hard surface areas like wood and glass.

The ability to publish on diverse products opens up countless possibilities for companies throughout various markets. In the advertising items sector, firms can tailor a large range of items, from carry bags and caps to cups and phone situations, all with the same printing modern technology. In the fashion business, DTF printing enables developers to try out intricate patterns and lively colors on unique fabrics, pressing the boundaries of creative thinking.

Additionally, DTF printing's compatibility with different materials also translates to cost-efficiency and reduced waste, as producers can utilize the very same equipment for several applications. This adaptability not just broadens the range of product offerings yet additionally enhances operational effectiveness.

Future Leads of DTF Printing

As the marketplace evolves, the future potential customers of DTF printing are positioned to change various markets with continual innovation and technological improvements. The rise popular for customized clothing and marketing products is driving the demand for extra efficient, flexible, and economical printing methods. DTF printing, with its ability to produce top quality, long lasting prints on a large variety of products, see this site stands at the center of this transformation.

Arising fads suggest that DTF printing will significantly integrate with automation and AI modern technologies, enhancing manufacturing rate and lowering labor prices. Advanced software services will additionally maximize design precision, shade matching, and print consistency, resolving some of the current restrictions. In addition, environment-friendly inks and recyclable transfer movies are anticipated to obtain traction, aligning with global sustainability goals.

Industries past fabrics are additionally checking out the potential of DTF printing. The innovation's adaptability makes it ideal for applications in home décor, vehicle interiors, and also clinical tools. As study and advancement efforts continue to increase, the range of DTF printing will likely broaden, opening up new opportunities for creative and commercial applications. In recap, the future of DTF printing is bright, encouraging considerable developments and more comprehensive industry fostering.

Verdict

Recognizing DTF Printing Modern technology notes a substantial innovation in the fabric printing sector, specifically for its versatility and efficiency. Direct-to-Film (DTF) printing is an innovative procedure that includes printing styles onto unique transfer movies, which are after that transferred onto material making use of heat and stress. DTF printing is specifically advantageous for limited-run orders and one-off pieces, providing a economical and efficient service contrasted to standard display printing techniques.

Unlike traditional printing approaches, DTF (Direct-to-Film) printing can be applied to an extensive array of substrates, consisting of cotton, polyester, blends, leather, and also difficult surfaces like timber and glass.DTF printing technology is changing the custom-made clothing market by offering reliable, cost-efficient, and functional remedies for creating dynamic styles on different materials without pre-treatment.

Report this page